|

Modern brake systems have always generated many fine dust particles.

|

|

|

|

Dear [FIRSTNAME],

Modern brake systems have always generated many fine dust particles. But now there is a new challenge: brake oxidation. With this in mind, car manufacturers are rethinking brake disk technology. |

|

TOP STORY |

|

|

|

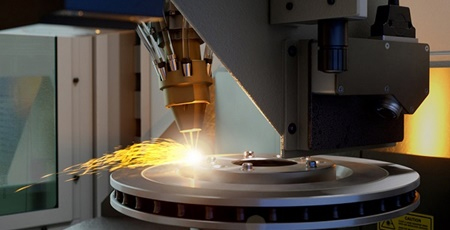

Production solution for coated brake disks

The car brake disk of the future is wear-resistant – and lasts as long as the car. This is made possible by a two-layer carbide coating that is applied to the disk using laser welding. EMAG LaserTec is currently engineering the associated integrated machine solution with the name ELC 450 LMD. The machine incorporates laser metal deposition into a comprehensive process that includes quality assurance. What exactly is special about the production solution from EMAG? More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

|

|

From manufacturing to intelligent manufacturing

An electric motorcycle can be produced in 30 seconds, with a frame accuracy error of less than 0.5 mm. Located in the China-ASEAN New Energy Electric Vehicle Production Base, the intelligent factory in Guangxi Luyuan Electric Vehicle has been fully launched, in which the modern workshops will realize strong manufacturing in quality more than the mass manufacturing in output, according to the Publicity Department of Gangbei District, Guigang City. More...

|

|

|

|

|

How manufacturers can achieve 90% machine use reduction with power

Tesla's automobiles are frequently cited as examples that electric vehicles (EVs) don't need multiple gears or dual transmission. That is, except for all the models that does. As the multi-gear EV trend begins to pick up speed Mats Wennmo, Global Automotive Transmission Manager at Sandvik Coromant, the global leader in metal cutting, explains how a process known as power skiving can help EV manufacturers keep-up, but with greatly-reduced machining times. More...

|

|

|

Schaeffler CEO on the future of electric vehicles in Asia

The increasing environmental and sustainability awareness issues accompanied by growing interest among consumers in sustainable vehicles, such as EVs have seen the automotive industry moving towards zero emission vehicles and carbon neutral manufacturing. Schaeffler has seen rise in demand for e-Mobility and EVs. In light of this, Mr. Dharmesh Arora, APAC CEO, shared his view on APAC e-mobility future and how to strengthen EV technology.

More...

|

|

|

Schunk's Tandem PGS3 pneumatic clamping vise

Collaborative robots and integrators have made it easier to implement automated machine tending. Small to medium size manufacturers are making the investment into automation and seeing returns in less than six months. The Schunk Tandem PGS3 vise features reliable, quality construction, the Tandem PGS3 reflects Schunk's 75 years of experience at building components for the industrial automated manufacturing industry.

More...

|

|

|

Aluminum top hat provides automakers a lighter, sustainable alternative

Alumobility, a non-profit organization focused on technical studies to advance the adoption of aluminum automotive body sheet, has revealed the results of its newest study demonstrating that an aluminum automotive top hat, the upper structure of a vehicle's Body-in-White, can save significant weight compared to steel while meeting or exceeding automakers' performance criteria. More...

|

|

|

|

|

|

|

|

|

|