|

Conversational programming provides the flexibility you need to bring order to the chaos of high-mix/low volume manufacturing.

|

|

|

|

|

Dear [FIRSTNAME],

Conversational programming provides the flexibility you need to bring order to the chaos of high-mix/low volume manufacturing. In addition to the basic ease and speed of programming, conversational programming offers another key benefit that CAM programming does not: flexibility. |

|

|

|

TOP STORY |

|

|

|

Is Conversational Programming Dead In Today’s Machine Shop?

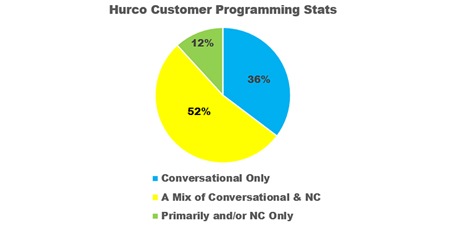

In the vast majority of these job shops, there has been at least one CNC machine with some type of conversational programming – and in many of these shops, they used conversational programming for most of their work. Customers survey stats show that when you combine the yellow and blue portions of the pie chart, you will notice that 88% of customers still find conversational programming helpful and useful, and find it a relevant way to produce parts - even in today’s supposed “CAD/CAM only” manufacturing environment.

More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

Laser system for half- and shingled-cell cutting in photovoltaic manufacturing

3D-Micromac introduced an advanced laser cutting system for half- and shingled solar cells – the microCELL MCS. The new microCELL MCS advanced laser system has been designed to meet the PV market's demands for boosting module power output and service life by minimizing power losses and providing for an exceptionally high mechanical strength of cut cells. It enables the highest throughputs for cutting cell sizes up to M12/G12 into half-cells or shingled cells. More...

|

|

|

Lasers present no threat to the grinding sector

Many users still machine CFRPs using tools with geometrically defined cutting edges. But this results in high wear levels during drilling and milling. The Institute of Machining Technology has developed an alternative diamond grinding process, which is significantly more economical. Professor Dirk Biermann is expecting to see interest in this grow as the number of CFRP processing operations rises. More...

|

|

|

Ansys to transform metal stamping through launch of Ansys Forming

Ansys Forming enables early stage and detailed design configurations by allowing users to preset varying simulation needs, including feasibility, formability and springback prediction. Through this end-to-end workflow, engineers can perform the entire die process on a single platform, eliminate the need for physical testing, and enhance productivity and cost savings. Ansys Forming reaches optimum performance by maintaining predictive accuracy and speed. More...

|

|

|

Optimized milling for vibration-free machining

Sandvik Coromant has launched a new high-feed milling tool. The CoroMill® MH20 is primarily designed for milling cavities, or pockets, in ISO S, M and P materials. Ensuring secure and vibration-free machining, especially at long overhangs, the tool delivers best-in-class edge security for a variety of industries and is particularly suited for machining aerospace components. Its ability to machine at long overhangs makes it especially beneficial to the aerospace sector. More...

|

|

|

Machine Tools – Fit for the digital future

"The digital future begins with C.O.R.E.," stresses CEO Stephan Nell. The new hardware and software architecture was developed by United Grinding specialists and premiered at the EMO 2021 in Milan. It opens up remarkable possibilities for networking, controlling and monitoring the production process and thus also for process optimization. And more: C.O.R.E. brings the user experience of operators into the world of the smartphone generation. More...

|

|

|

WIDIA presents face milling suitable for variety of machine conditions, set ups

WIDIA announced the release of the M1600 face mill for roughing to semi-finishing operations in steel, stainless steel, cast iron and nodular iron materials. With 16-cutting edges and a smart insert design, the M1600 performs in various machining conditions including low-power machines, unstable, non-rigid set ups, long overhangs, weak machines or weak fixture conditions. More...

|

|

|

|

|

|

|

|

|

|

|