|

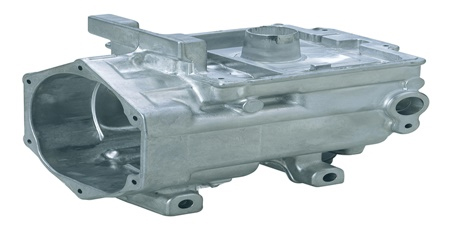

The die casting process is challenging to manage due to a range of constantly changing production conditions

|

|

|

|

Dear [FIRSTNAME],

The die casting process is challenging to manage due to a range of constantly changing production conditions. Success relies on the judgement of experienced workers, and sometimes the parts require secondary processing to maintain high quality standards. |

|

TOP STORY |

|

|

|

Digital transformation for die casting

Toyota Industries Corp. and Siemens have cooperated to develop artificial intelligence (AI) that can predict product abnormalities in aluminum die casting, a key process in automotive air conditioning compressor production. The development is one of the world's first to use defect prediction AI for die casting. It improves quality and productivity by utilizing the AI application in Industrial Edge. The initiative is an innovative example of digital transformation in manufacturing. More... |

|

TECHNICAL HIGHLIGHT |

|

|

|

Compact manufacturing solution for large brake drums in commercial vehicles

It's clear that trucks are set to remain the most important means of transport for the logistics. This increase in demand is also being felt by manufacturers, so they are constantly on the lookout for highly productive and reliable manufacturing solutions in this segment. When EMAG was asked by a leading manufacturer if it could apply its expertise from the automotive industry to the manufacturing of truck brake drums, the response was easy. More...

|

|

|

Breakthrough in aluminum sintering for binder jetting technology

Desktop Metal and Uniformity Labs announced a breakthrough powder that enables aluminum sintering for binder jetting AM technology. The fully dense, sinterable 6061 aluminum with better than wrought strength will be available for binder jetting technology, marking a significant step forward for the Additive Manufacturing (AM) industry as it is one of the most sought-after materials for use in automotive, aerospace and consumer electronics. More...

|

|

|

|

|

|

|

A turnkey solution for automotive laser welding

Coherent, and II–VI Incorporated have entered into a supply agreement creating a collaboration to enable faster process development and streamlined production services for automotive laser welding applications. These include high-strength alloy welding for automotive body-in-white applications and mass production copper welding for electrification applications. More...

|

|

|

WALTER HELICHECK 3D ensures quality of tools for various industries

Production demand is expected to surge in industries such as light and heavy vehicles, defense, construction machinery, civilian aircraft and medical, and particularly in applications that involve cutting tools of all types. To meet these growing tooling needs, the WALTER HELICHECK 3D optical non-contact 4-axis CNC measuring machine from UNITED GRINDING adds to the precision of tool grinding operations for these challenging applications. More...

|

|

|

Efficient turning with exchangeable head boring bars

Quality and efficiency in the machining process are measured using an extremely wide range of parameters. Naturally, surface quality and process security are among them. The new vibration-damped boring bars by Team Cutting Tools from the CERATIZIT Group ensure that these criteria are met. These boring bars reliably reduce vibrations and, together with the flexibility of the brand-new exchangeable head system, guarantee top quality at a low price.

More...

|

|

|

Hexagon boosts productivity with high-performance cross-platform scanner

Metrology-assisted automation is widely regarded as fundamental to future large-scale manufacturing, said Daniel Moser, Technical Product Director at Hexagon. Laser tracker-based systems have an important role to play in that future, primarily in ensuring quality isn’t sacrificed in the pursuit of increased productivity.

More...

|

|

|

|

|

|

|

|

|

|